Industry 4.0 and AI drive increased efficiency, flexibility, and innovation in manufacturing and other industries, enabling real-time data analysis, informed decision-making, and adaptive responses to changing market demands, ultimately fostering a competitive edge and cost savings.

Minim dolor in amet nulla laboris enim dolore consequatt.

Minim dolor in amet nulla laboris enim dolore consequatt.

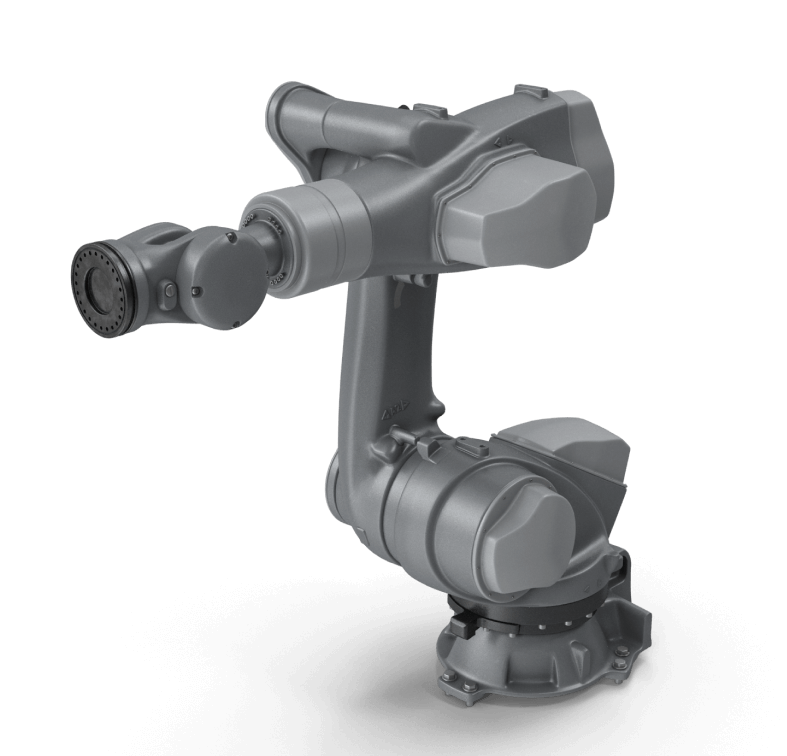

The Vision Failure Analysis Machine is an advanced diagnostic tool designed to automatically inspect, identify, and analyze defects in various products or components through the use of sophisticated imaging and vision technologies. This machine leverages high-resolution cameras, machine learning algorithms, and AI-powered image processing to detect and diagnose faults with exceptional accuracy and speed.

Offers significant benefits by enhancing quality control through its ability to detect even the smallest defects with high-resolution imaging and real-time analysis. This automated system increases inspection speed and efficiency, reducing manual labor and associated costs, which leads to substantial operational savings. By identifying defects early in the production process, it minimizes waste and the need for rework, ensuring that only high-quality products reach the market. Additionally, it provides valuable data-driven insights that can be leveraged to improve production processes and product designs, ultimately fostering higher product integrity, customer satisfaction, and competitive advantage for companies.